مركز الملك سلمان للإغاثة يوزع آلاف من الحقائب الشتوية في مناطق كوهستان وشترال العليا وشترال السفلى بإقليم خيبربختون خوا في باكستان | الأخبار | جريدة النور

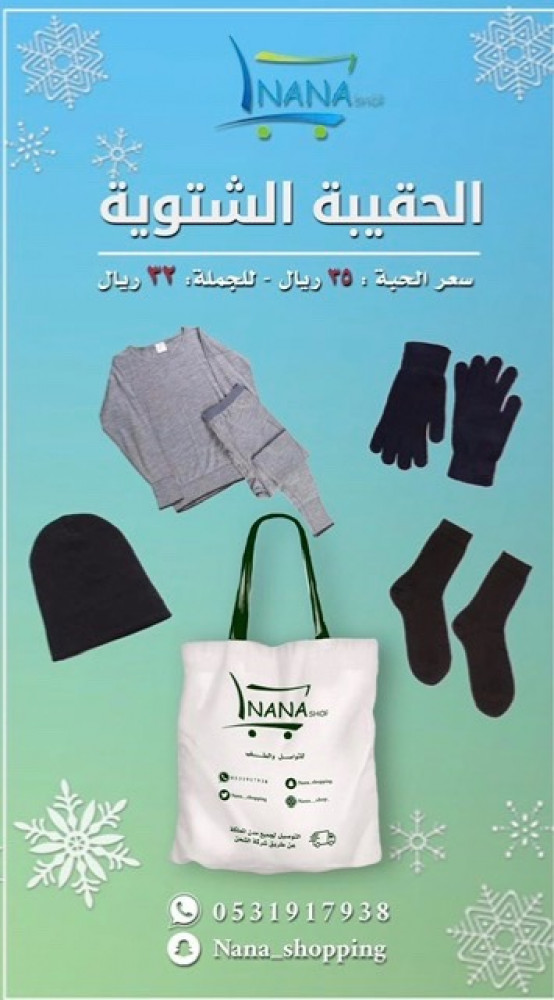

مؤسسة الحقيبة الشتوية on X: "#الشتاء ابتدأ .. ❄️ هذي فكرة إنسانية بسيطة لمن يُريد الأجر .. الحقيبة الشتوية مناسبة للتوزيع في الأجواء الباردة .. ⛄️ جزى الله من ساهم بنشره كل

مؤسسة الحقيبة الشتوية on X: "بردان صح ؟ الجو برد صح ؟ لابس ومتدفي صح ؟ فماذا عن عمال النظافة والمحتاجين !! خلّونا نهديهم #الحقيبة_الشتوية 💪🏻 https://t.co/lZXZNZf3lf" / X

كونا : (الهلال الأحمر) الكويتية توزع الحقيبة الشتوية على العمال في القطاعات الصناعية والتجارية - انسان - 22/12/2018

روزفراي حقائب توتس للاطارات الموسمية، غطاء اطار احتياطي، عجلة شتوية محمولة، مقبض لسهولة النقل، يناسب اطارات بقطر 21 انش الى 31.5 انش، مجموعة من 4 حقائب بلون ازرق : Amazon.ae: السيارات